How GM’s Fast-Moving Recruiters Helped Save Lives

For recruiters, finding talent is always critical. But recently, for the recruiting team at General Motors, it became a matter of saving lives during a pandemic.

In mid-March, GM and Ventec Life Systems of Bothell, Washington, began working on a plan to rapidly expand production of Ventec’s VOCSN critical care ventilators to help COVID-19 patients in the United States. Virtually overnight, a small group of GM recruiters started looking for production workers in and around the city of Kokomo, Indiana.

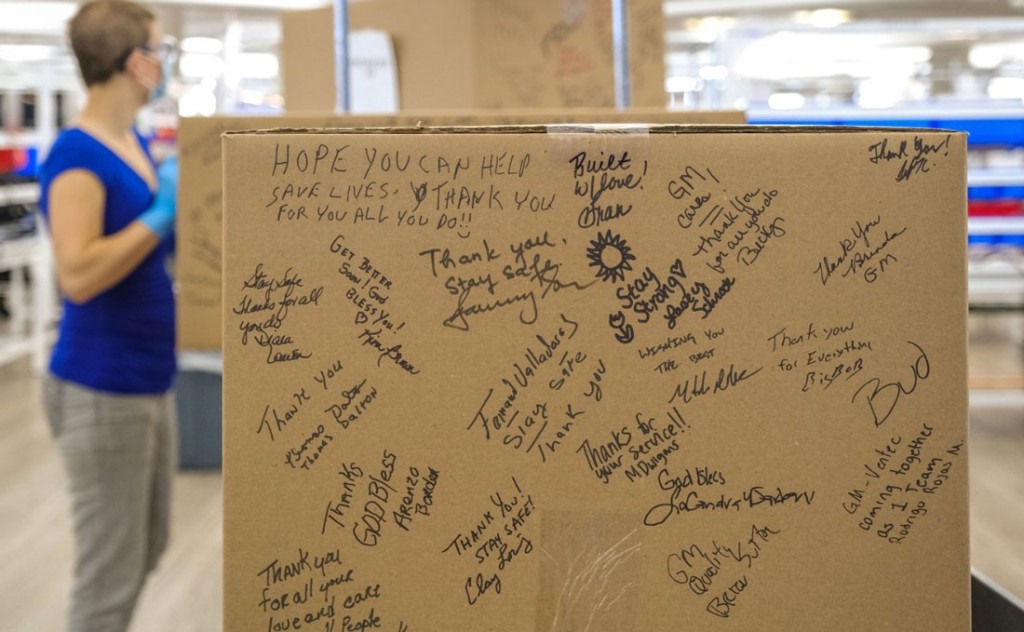

The team employed hustle, creativity, and grit to find the right people to make a highly sophisticated piece of life-saving equipment that is unlike anything else GM produces. They worked long hours, met unexpected obstacles, and, miraculously, went from posting jobs to shipping hundreds of FDA-approved VOCSN V+Pro ventilators in just three weeks. They simply refused to say no.

“There were many challenges along the way,” says Ashley Winnett, GM’s global head of talent acquisition, “but knowing that if we didn’t begin shipping in April, there was a potential someone would have died, and that was more stressful than anything I’ve ever faced.”

More than 600 ventilators were shipped to hospitals and FEMA by the end of April. By the end of August, GM expects to deliver 30,000 ventilators to the U.S. government.

Weiss Memorial Hospital receives a shipment of VOCSN critical care ventilators Friday, April 17, 2020 in Chicago, Illinois.

Ashley takes pains to focus on the heroics of the frontline healthcare professionals who are putting the GM-made ventilators to life-saving use, yet his fast-acting recruiters have more than earned a shout-out too. They have assembled two full shifts of 300 workers each and are now pulling together a third shift.

Here’s how they did it:

1. They had their job posts ready to go and, when they started hiring, actively looked for referrals

On March 25, the GM recruiting team was told to get ready to hire people for three work shifts at the company’s Kokomo factory, which is normally used to build precision electrical components for GM vehicles. Two days later, a press release announcing the GM-Ventec partnership came out at 5:30. “At 5:31, we got out there on LinkedIn,” Ashley says. “We had our jobs ready to go.”

In some ways, it seemed like a perfect time to be posting hundreds of jobs — some companies had already enacted hiring freezes and others had started layoffs. And the work would be enormously impactful, helping to save lives, directly and immediately.

GM also typically gets a lot of candidates from referrals. Starting from scratch, that wasn’t initially an option. But as they began to hire, Ashley says, they told each new employee: “Look, you’re a great person, and great people tend to know other great people.” They then handed the person a flyer with a QR code and encouraged the new hire to ask friends, relatives, and neighbors to apply.

When some new hires didn’t show up for work, GM reached out and interviewed them to find out what had caused them to change their minds and to discover what GM could do to make the jobs more attractive.

2. They adapted their marketing materials to show safety precautions and underline the importance of the work

As GM's recruiters talked to the first-day no-shows as well as the eager new hires, they learned two important things: First, a lot of people who accepted jobs didn’t show up because they were concerned about their personal safety. Second, a lot of the people who did show up invoked Rosie the Riveter, the WWII icon who represented the millions of U.S. women who left home to work in factories and shipyards during the war.

To the first point, GM knew safety would be a concern. But when Ashley’s team started recruiting, the Kokomo plant hadn’t yet been converted to produce ventilators. Because they couldn’t sell the plant, they sold the process. Their marketing materials focused on the processes and personal protective equipment in place to keep employees as safe as possible. And once the factory was up and running, the recruitment marketing team also produced videos of Gerald Johnson, GM’s head of manufacturing, and Dr. Jeffery Hess, the company’s chief medical officer, talking about the safety measures taken at the Kokomo plant.

To the second point about the importance of the work, the team also created assets that underscored the opportunity ventilator assembly workers would have to save lives.

Nicholas Wampler builds production ventilators at the General Motors manufacturing facility in Kokomo, Indiana, Tuesday, April 28, 2020.

“Workers would tell us they had a relative who had pitched in during World War II,” Ashley says, “now they are going to do their part to fight COVID.” To drive home the point about the team’s mission, GM produced videos showing doctors and nurses at Chicago’s Weiss Memorial Hospital lining the sidewalk to receive the first Kokomo-made ventilators on April 17.

3. They reassessed their assessments

Once candidates apply (GM still is hiring, for both full- and part-time jobs in Kokomo), recruiters conduct a phone screen. Candidates who move forward are given an online work environment test that measures psychological traits and certain cognitive abilities.

While GM has well over a century of manufacturing experience, that know-how is focused on building vehicles like Corvettes, Cadillacs, and Chevy pickup trucks, all vehicles assembled from large parts. The VOCSN V+Pro has hundreds of parts, most of them quite small.

“When you build a ventilator,” Ashley says, “you don’t use hammers and gimbal guns. You use tweezers.” So, GM needed a dexterity test that would give the TA team an accurate idea of which candidates could adeptly manipulate very small screws.

Workers prepare to build ventilators at the GM manufacturing facility in Kokomo, Indiana, Monday, April 6, 2020.

Ashley’s team consulted with an industrial psychologist and industrial engineer about what kind of tests might work best. “And then,” Ashley says, “as daft as it might sound, we jumped on Amazon thinking, ‘We’ll just go online and buy some tests off the shelf.’”

Which they did. And as soon as the tests arrived, they put them to, well, the test. GM’s industrial psychologist ran candidates through the tests to measure their effectiveness. Dexterity for posterity.

4. They rethought how to conduct background checks and drug tests

Once GM had found the smart, dexterous workers they were looking for, they needed to do background checks and drug tests.

But background checks usually start at the county courthouses and most of those were closed in Indiana. So, the GM team adapted, getting what it could from state and federal sources and putting a contingency into their offer letters noting that continued employment would be dependent on nothing coming back from the county — once courthouses reopen — that would preclude candidates from working for GM.

As part of their ongoing safety efforts, GM also does a drug test before finalizing offers. But some of their drug-testing options in the Kokomo area had been shuttered.

They continued to work with their existing roster of drug-testing companies, using all that remained open. They also brought doctors and nurses in from other GM facilities to conduct tests.

But that took time, so they got on their phones and the internet to see who else could do drug-testing and screening in the immediate Kokomo area.

“We were laughing,” Ashley recalls, “because I was saying — and this will age me — ‘All right, let’s grab the Yellow Pages and start looking them up.’” Their improvisational sleuthing expanded the number of companies they could turn to as they faced an onslaught of candidates.

Final thoughts: Recruiting during a pandemic can be challenging — and rewarding

What was the key to going from a request to start hiring to a finished product in three weeks?

Mindset, Ashley says. Because of the stakes, his team couldn’t say, “That’s impossible.” They had to find a way to say, “Yes, we can do that, and we can do it quickly.” And once they said yes, they found that a number of the obstacles that they would normally encounter disappeared. People wanted to clear the way rather than get in it.

The work has been challenging and exhausting. “I see all these posts about people binge-watching stuff and learning things and reading,” he says. “My team’s going to need a holiday after this to recover. They have worked tirelessly with a fair amount of pressure and a bunch of surprises along the way. But they’ve overcome it all.”

Instead of comparing Netflix recommendations, Ashley’s team is comparing notes about long hours and newly encountered obstacles. But mostly they’re talking about what a difference they’re making.

“They know these long hours are paying off,” Ashley says, “and they know the end result: There are people whose lives are being saved.”

To receive blog posts like this one straight in your inbox, subscribe to the blog newsletter.

Related articles